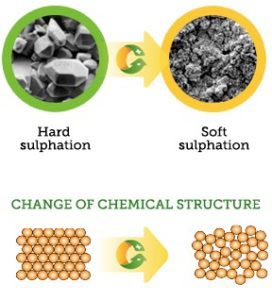

MacBatec Battery Regeneration Technology works on the hard sulphation, cracking the crystals as much as is technically possible. Reaching this level of efficiency is crucial. An incomplete desulphation would raise the battery temperature again, further speeding up crystallisation and dramatically reducing the benefits of the regeneration.

MacBatec Battery Regenerators restore lost battery capacity through carefully controlled current pulses.

The pulses break down the lead sulphate crystals that suffocate the battery and return them to their amorphous form (a process known as desulphation). The amorphous or spongy form is the active material used by regular and HF chargers to increase the specific gravity of the electrolyte and recharge the battery.

Crystals or hard sulphation is the inert material that causes damage to batteries. This is because they serve as insulation (offering a strong resistance to the flow of electric current) and also because they are physically larger (they pressure the electrodes mechanically

MacBatec’s level of efficiency, automation and long-term support ensure the best battery restoration and regeneration results.

Battery recondition can be done regularly through a maintenance service or once through a full service.

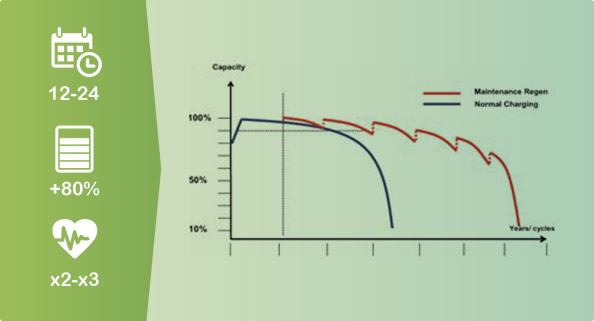

MacBatec Maintenance Battery Regeneration Service

This service is done regularly every 12-24 months while sulphation is still low, and the battery is at 80% or more of its capacity with no electromechanical damages. Through this regular maintenance, our battery regenerator will recover the battery level to nearly the maximum provided by the manufacturer and double or even triple the life span (depending on the battery type and application)

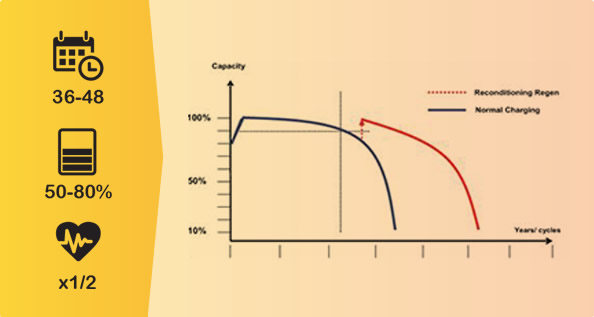

MacBatec Full Battery Regeneration Service

This service is for used batteries that have lost a significant portion of their capacity. Our battery regenerator will recover up to 50% of lost capacity, depending on the type of damage and how the battery recovery process is done. Be sure to follow up with maintenance services to keep the battery capacity at a high and uniform level

MacBatec offers the best battery economy through direct cost savings as follows:

1. Reduced battery consumption

A traction battery costs USD 3,000-11,000.- and typically lasts for 3 to 6 years.

Through MacBatec’s regular service, the life span for traction batteries is doubled from 6 to 12 years and battery costs are reduced by half. Since standby batteries suffer less vibration, their life span can be tripled.

The price of the MacBatec Battery Regenerator represents only a fraction of that cost.

2. Increased productivity for battery power systems

Most electric trucks and standby systems are designed for a battery capacity of 80% or more in order to provide the expected performance.

Crystallisation makes active material inert and thus lowers the capacity of the battery. Depending on the actual application and working conditions, the capacity of a traction power battery will fall below 80% after 1 to 2 years while a standby power battery will reach the same level after 3 or 4 years.

Our battery regenerator system helps to maintain battery capacity at its original level. This way, the forklift or mining truck will run for the entire shift and the uninterrupted power source (UPS) will always provide the expected power supply, avoiding expensive interruptions (e.g. delays in industrial processes, failures in emergency services at hospitals, data transactions or telecommunications).

3. Less wear and malfunctioning of electronic components

When battery voltage drops below its designed level, more current is needed to perform a certain task. Voltage variations and the subsequent surge in current results in wear and malfunction of electronic components –not to mention unnecessary repairs.

Regular MacBatec regeneration servicing keeps a cell’s voltage constant and uniform to avoid expensive electronic component failures.

4. Reduced power consumption

Because hard sulphation serves as insulation and offers a strong resistance to the flow of electric current, it will take longer to fully charge the battery, consuming more power that will be dissipated and lost as heat.

The MacBatec service destroys the lead sulphate crystals, reducing power consumption and slowing the formation of new crystals.

Increasing a battery’s life span means reduced battery consumption and thus global environmental benefits. Mining, the transport of lead and other raw materials, CO2 emissions, the transport for commercial distribution, premature recycling of used batteries, etc. are all reduced when a battery’s life span is lengthened.

Lead (Pb) is the chemical element with atomic number 82. Although it is classified as one of the heavy metals, it is soft, malleable and it melts easily.

As a heavy metal, lead is neurotoxic, which means that it accumulates in organic tissues and can cause disorders in the nervous system.

According to the International Lead Zink Study Group (ILZSG), the consumption of lead has been increasing worldwide, peaking at 11,000,000 tonnes in 2013. A little more than half of this was from recycled material and the rest was virgin metal produced in mines.

Most lead is used for lead-acid batteries. Other uses include radiation shielding material, bullets and shots and fusible alloys.

The regular MacBatec service can reduce lead consumption by half or one-third depending on the battery type and application.

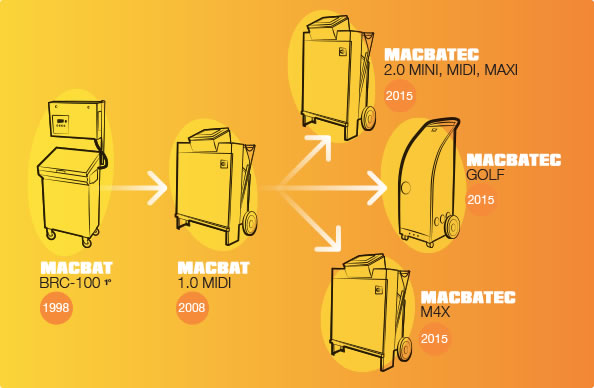

The diagram shows the evolution of our battery regenerator, from the first prototype launched on the market in 1998 (MACBAT BRC-100 1st Generation) to the current MacBatec 2.0 Mini, Midi and Maxi models that wear the most ultimate control software that has been created fo battery regeneration.

Any type of lead-acid battery, provided it is mechanically and electrically intact and has been adequately maintained, can be successfully recovered with our battery regenerator. This includes all standard ventilated batteries and valve regulated batteries such as GEL and AGM (absorbed glass fibre mat).

Please contact us for a recommendation of the device best suited to your needs.

Download our commercial flyers:

Our goal is to allow you to focus on your work, which is where you are more productive. Let us worry about your batteries, regeneration service, regenerator machines, etc.

In addition of developing and selling battery regeneration technology, we provide tailor-made training programs for your employees. Through these programs, we help you implement the best methods and procedures for your battery fleet; and assist you in managing your batteries from the time of purchase until the end of their life span.

Please contact us and let us come up with a solution that fits your needs.

Restoration methods and procedures designed first in Sweden and currently in Spain

Restoration methods and procedures designed first in Sweden and currently in Spain